Sheldon,

If you want an absolute black, I'd recommend either phenolic or Gaboon Ebony, but if you're open to a dark block inlay with some color and character to contrast the Maple you can consider other woods.

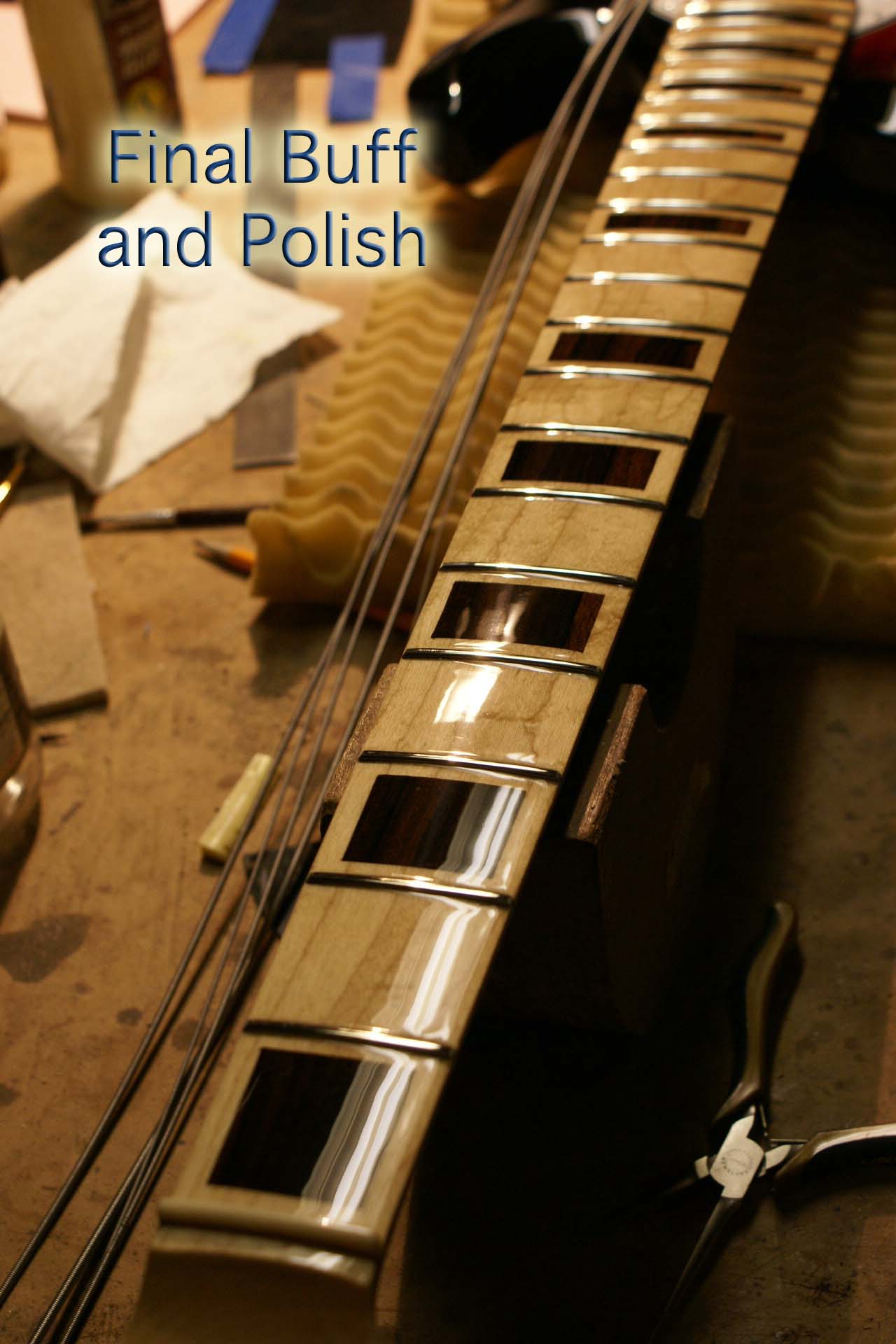

I recently converted a fingerboard on a Music Man 5 string used by my bass player in my church from dots to Zircote blocks and it looked great when it wa done.

Very dark with a hard contrast to the Maple, but with great lines ad color to add interest.

Here are a couple of photos of the inlays.

Regards,

Kevin Gallagher/Omega Guitars